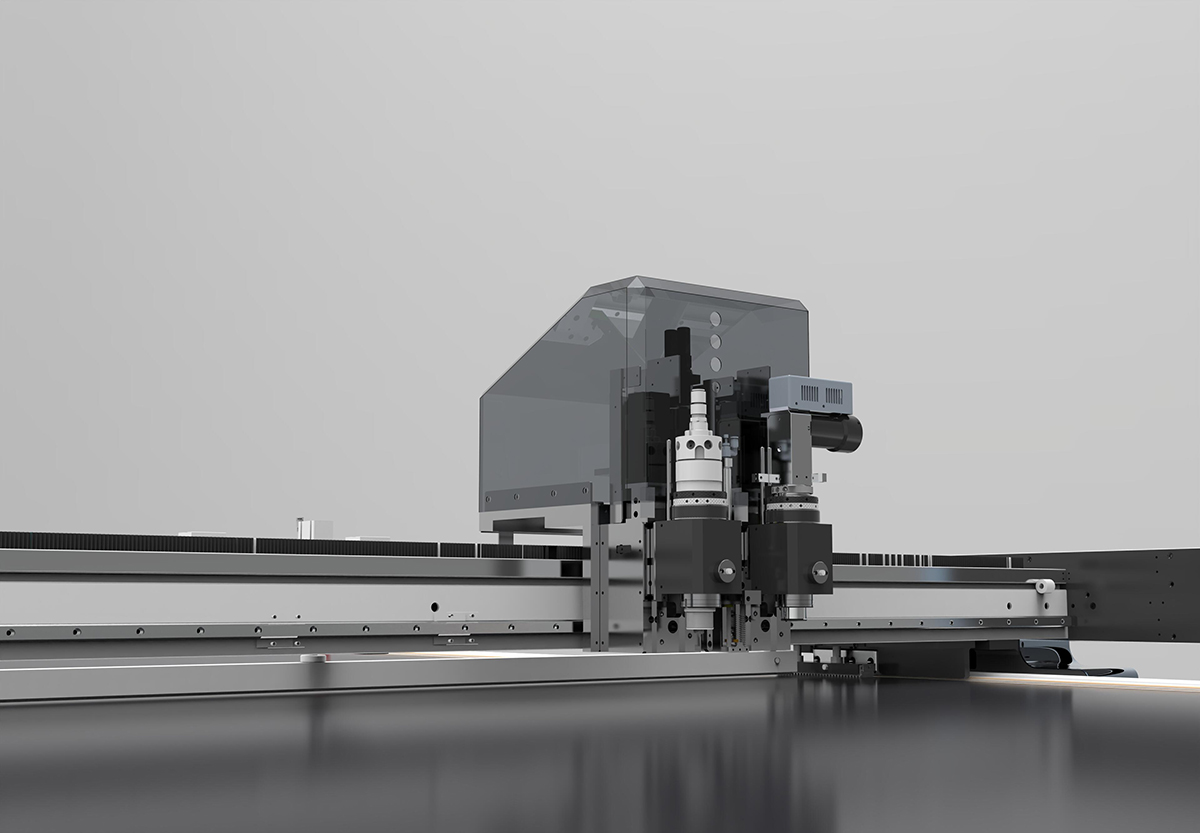

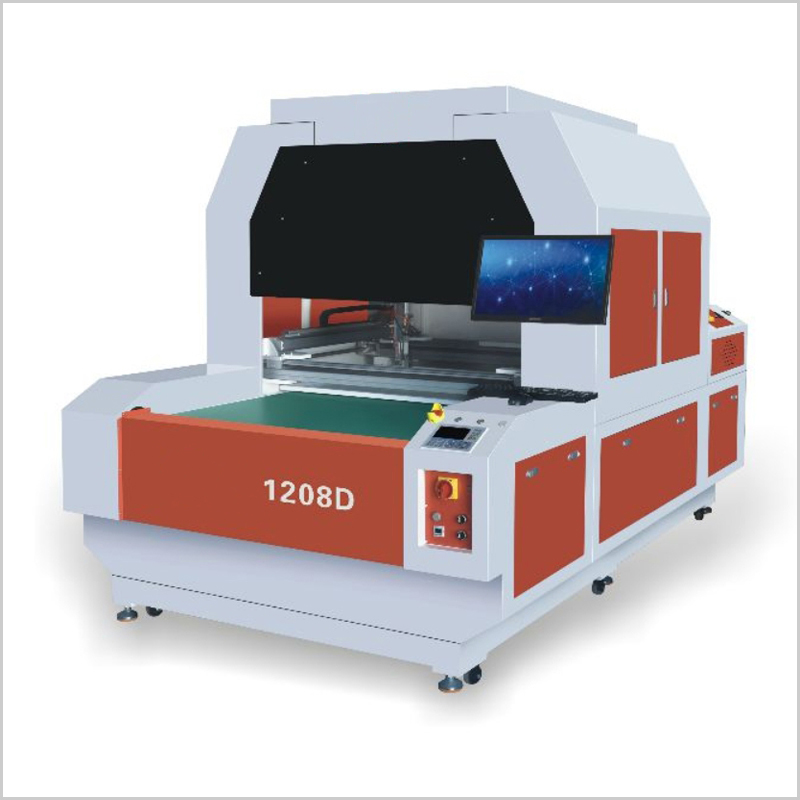

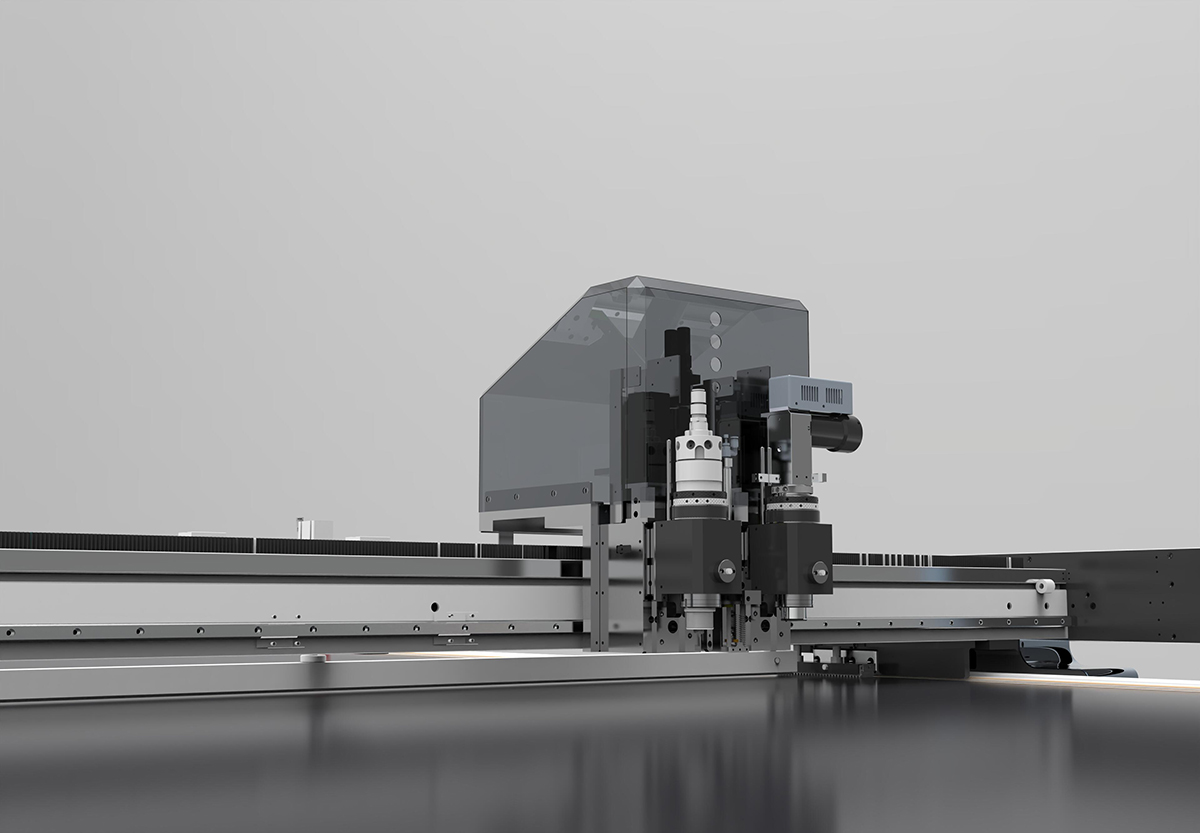

2516 High Quality Cnc Digital Oscillating Knife Leather Cutting Machine Vibrating Round Knife Fabric Textile Garments Cutter

2516 High Quality Cnc Digital Oscillating Knife Leather Cutting Machine Vibrating Round Knife Fabric Textile Garments Cutter

Brand name: DAFENG

Available cutting materials: gasket, composite materials, Polyester Acoustic Panels, Soundproof Panels, honeycomb board, corrugated board, cardboard, grey board, KT board, plastic sheet, fabric, PU, EVA, Car mats, etc.

Application: composite materials industry, carton boxes industry, packaging industry, shoe industry, cloth industry, automotive interior industry, etc.

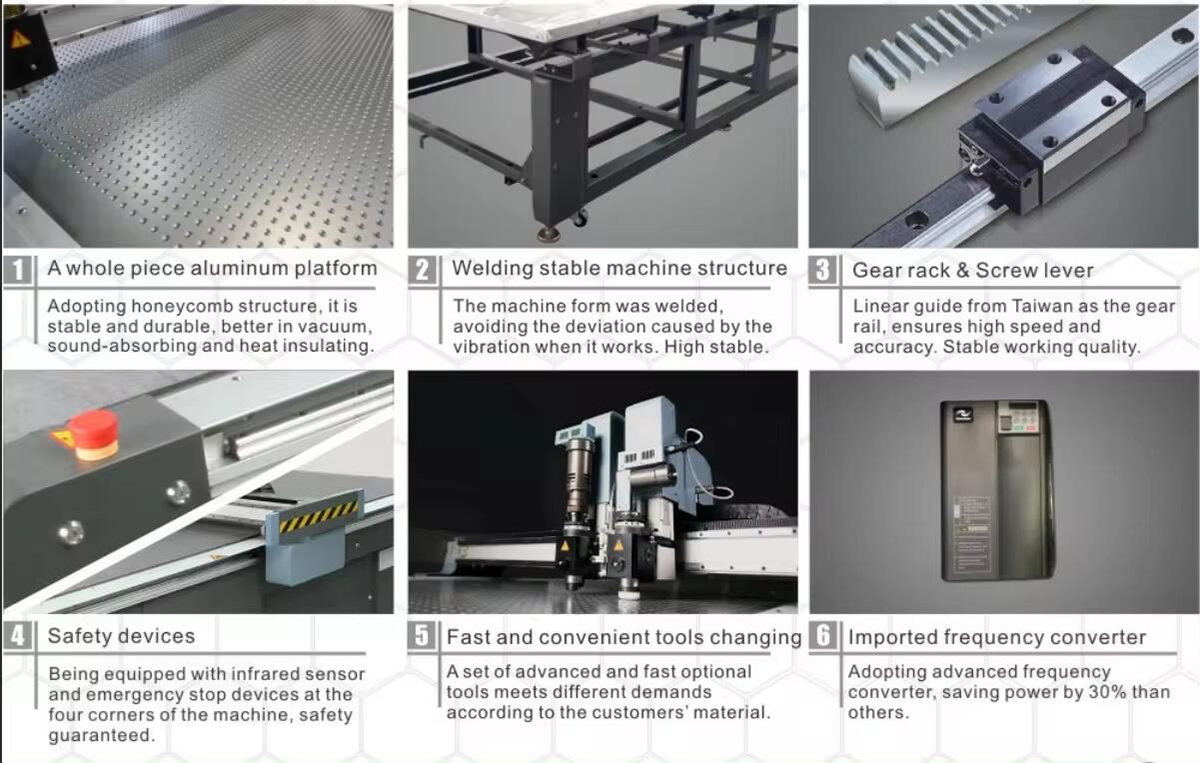

Functions: knife cutting, creasing, punching, drawing

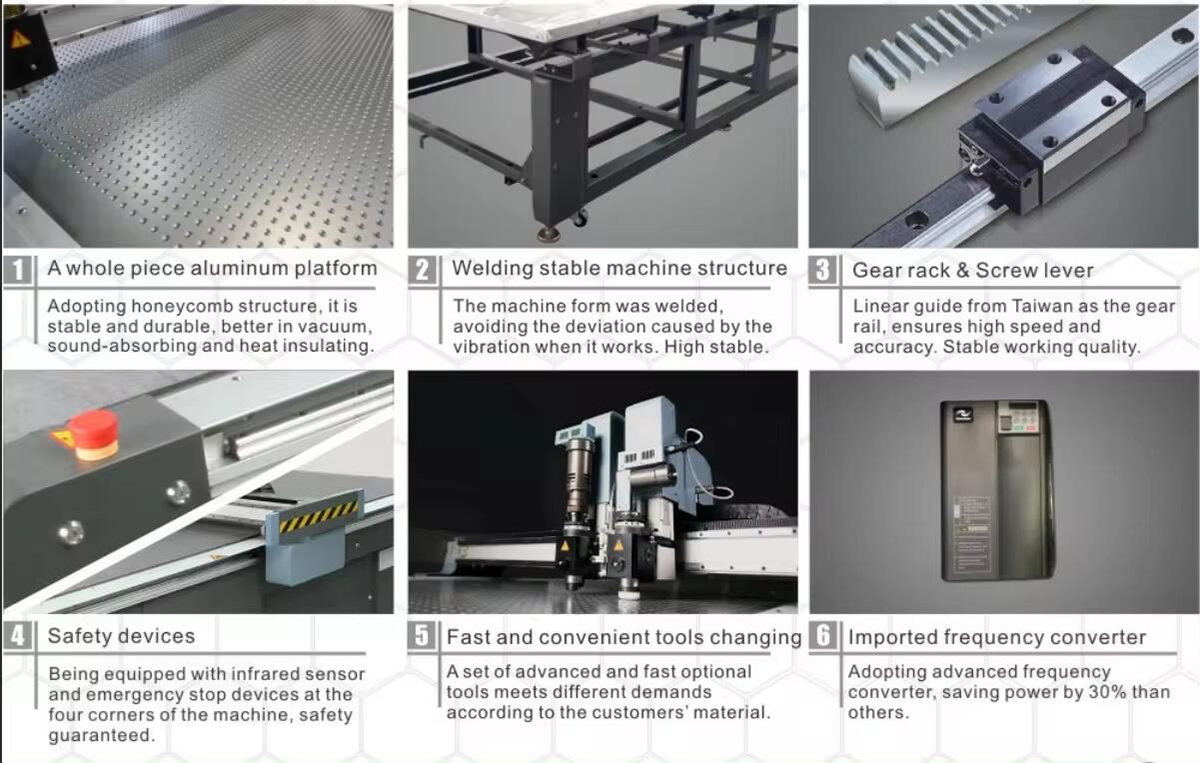

Equipments: cutting tools (Oscillating knife,), CCD positioning system,advanced frequency converter.

Features: multifunctional, user-friendly, safety, power saving, materials saving

|

Model of cutting machine |

DFCRT-2516EF |

|

Effective working area |

2500mm*1600mm |

|

Cutting speed |

1-1200mm/s |

|

Cutting thickness |

0.1-50mm |

|

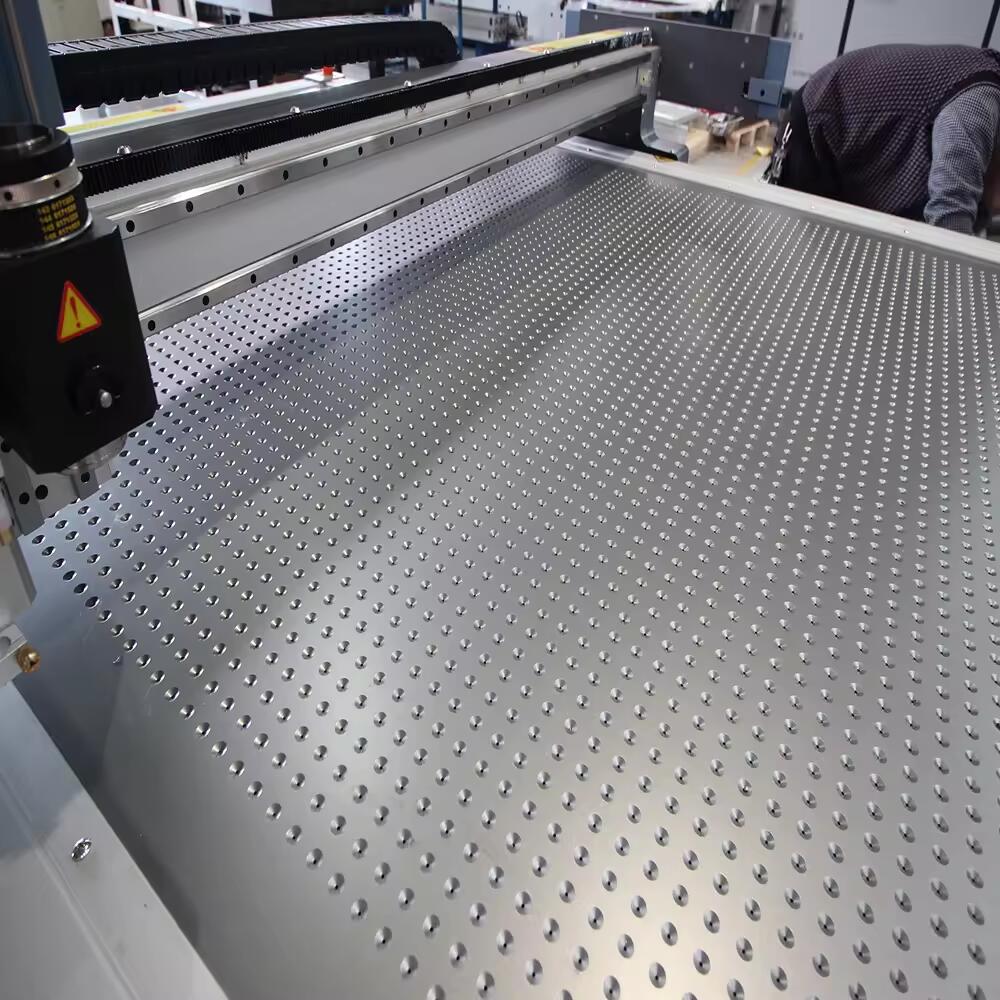

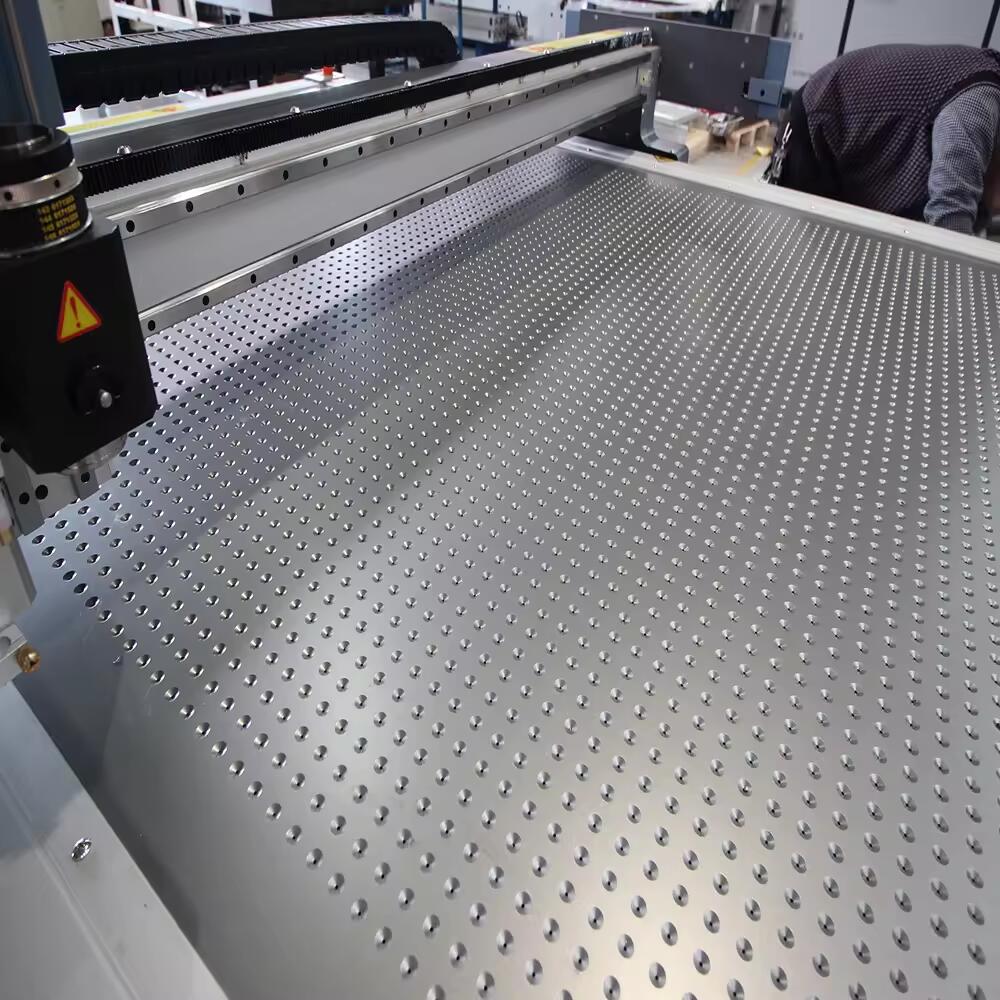

Method of fixing material |

Divisional vacuum absorption |

|

Knifes |

Oscillating blade head, Milling Cutter, Hobbing Cutter, Creasing Wheel |

|

Pen types |

Common signing pen, Oil pen, ball-point pen, Silver pen |

|

Human Machine Interface (HMI) |

Touch screen LCD |

|

Machine resolution |

0.01mm |

|

Software resolution |

0.025mm |

|

Interface of transmission |

Network port |

|

Gearing |

Linear guide and gear rack |

|

Motor |

Servo motor |

|

Machine voltage |

220V/380V |

|

Air pump power |

9KW |

|

Energy saving device |

Frequency converter |

|

Software system |

Independent research and development CNC software |

|

Control system |

Cutting table and computer display |

DAFENG CRT cutters are consistently geared towards automated digital cutting of a

wide variety of materials. For lightweighting applications, RUIZHOU offers powerful, cost-

effective and expandable cutting solutions. Our tools are also reliably to cut paper, PU, fabric,

PVC foam composite etc.

|

Model |

DF-CRT5-2516EF-25C |

DF-CRT5-2516EF |

|

Ref. Image |

|

|

|

Cutting Area |

2500 x 1600 mm |

2500 x 1600 mm |

|

Sorting Area |

2500 x 1600 mm |

/ |

|

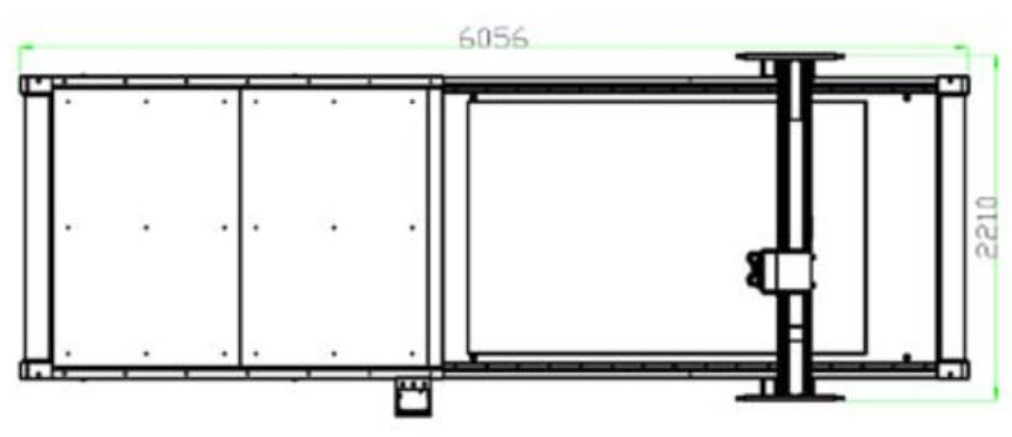

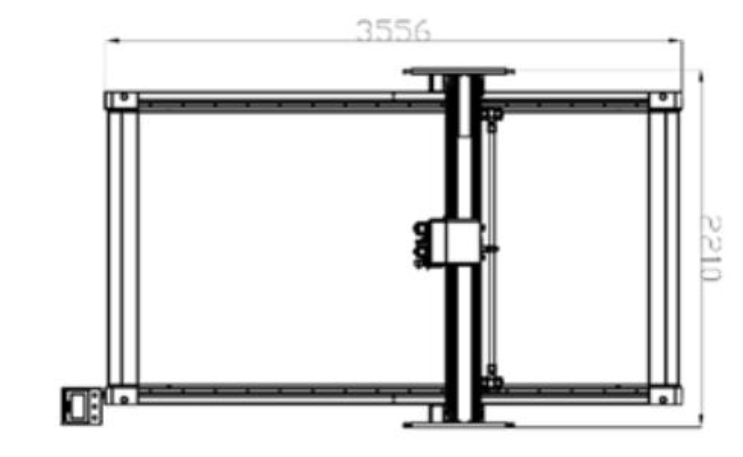

Machine Size |

|

|

|

Cutting Head |

Two modulars cutting head |

|

|

Table Type |

Conveyor belt table with automatic feeding function |

|

|

Cutting Tool |

Pneumatic oscillating tool / Electric oscillating tool + punch tool + pen |

|

Digital cutting workflow on DFCRT5-2516EF-25C

|

DFCRT5-2516EF-25C |

|

|

1. Load |

Spread material on machine |

|

Import pattern file to DAFENG cut program |

|

|

2. Cut |

Send the marker to cut on machine, check the position of marker and make sure all pieces are placed inside material then start cut |

|

3. Unload |

In DFCRT5-2516EF-25C, when cutting is finished, move the cut pieces to the sorting area. In the meantime, new material will be fed to the cutting area. Start cutting next page, then operator can collect the cut pieces and remove the wastes from table |

|

In DFCRT5-2516EF, when cutting is finished, pause the machine and collect the pieces. Then feed new material and start cutting next page. |

|

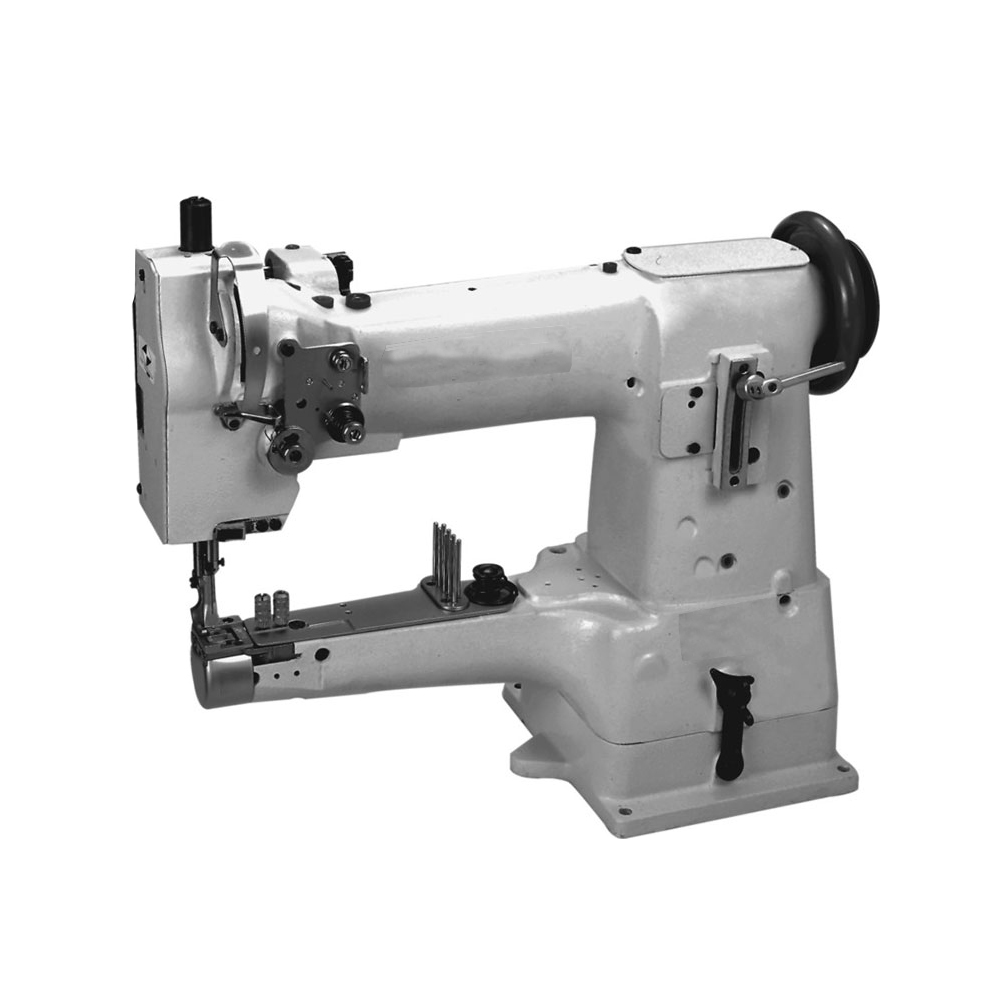

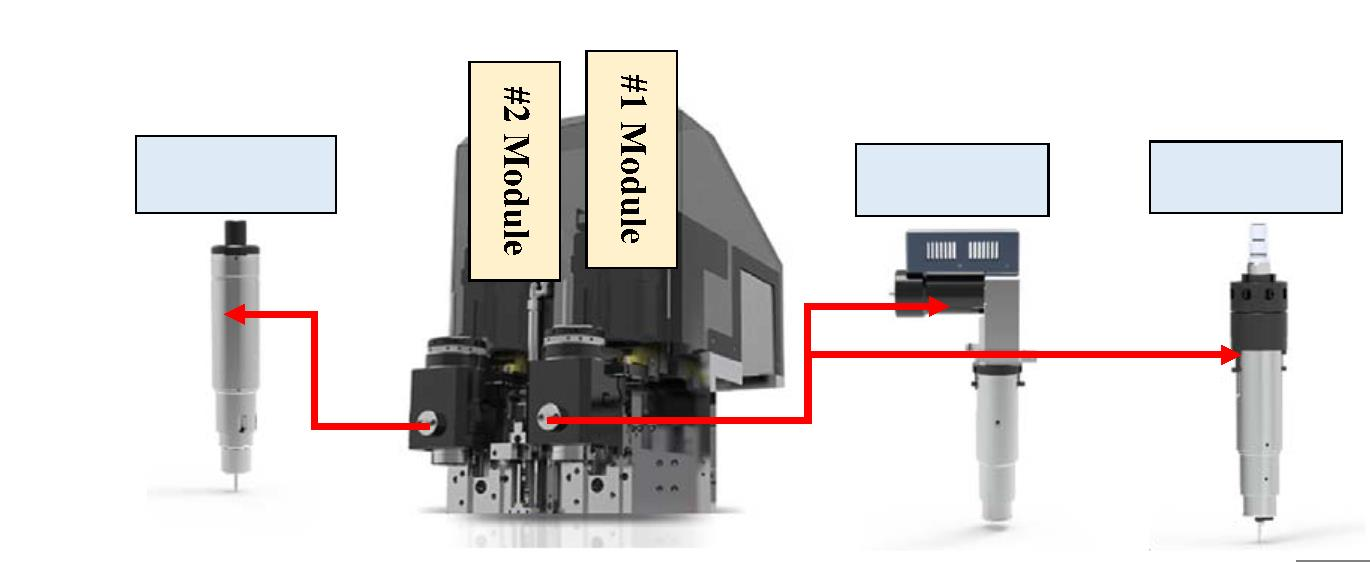

Introduction of Cutting Head & Tools

2-Modular Cutting Head

#1 Module, installs electric oscillating tool or pneumatic oscillating tool to handle the work of cutting.

#2 Module, installs punch tool to cut drill small holes.

|

Electric Oscillating Tool (EOT) Rotation speed: 1600~17800 rpm/min Stroke: 0.5 mm Knife clip: 0.63mm or 1.0mm Motor driven, cut single layer |

|

Pneumatic Oscillating Tool (POT)

Stroke: 8 mm Knife clip: 1.0mm Compressed air driven, cut single layer or multiple layers, suitable for hard or thick material like foam or EVA, requests for stable compressed air supply. |

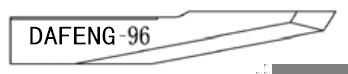

Recommended blade model

|

Model: DFCUT-27 Thickness: 0.63 mm Cut single layer |

|

|

Model: DFCUT-96 Thickness: 1.0 mm Cut both single layer PU foam and multiple layers PU |

|

|

Punch Tool

Optional punches size (11 sizes): D=0.8/1/1.2/1.5/2/2.5/3/3.5/4/4.5/5 mm |

|

TECHNICAL SPECIFICATION

|

DFCRT5-2516EF-25C |

DFCRT5-2516EF |

|

|

Cutting Area: |

2500*1600mm |

2500*1600mm |

|

Sorting Area: |

2500*1600mm |

/ |

|

Cutting Speed: |

500-1500mm/s |

|

|

Cutting Thickness: |

0.5-25 mm |

|

|

Processing Materials: |

Microfiber, PU leather, synthetic leather, PU foam, fabric, mesh, cardboard etc. |

|

|

Hold Method: |

Powerful vacuum absorption with multiple sections Conveyor belt table, automatic feeding material |

|

|

Standard Configurations: Machine Table: |

Cutting Head |

2-modular cutting hea |

|

Cutting Tool

|

Electric oscillating tool or Pneumatic oscillating tool |

|

|

Punch Tool |

Vertical drilling tool |

|

|

Drawing Tool |

Silver-pen tool |

|

|

File Formats: |

Standard DXF, PLT & HPGL |

|

|

Compatibility: |

Optitex, AutoCAD, CorelDraw etc. |

|

|

Keyboard Language: |

Chinese, English, Korea … |

|

|

Transmission Interface: |

Net port |

|

|

Accuracy: |

± 0.3mm |

|

|

Vacuum Power: |

9 KW, 3-Phase 380V/50Hz |

|